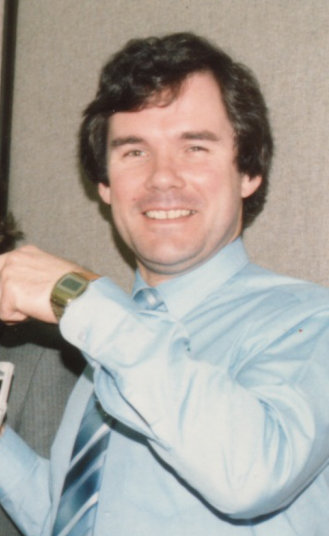

Derek Williams circa late 1984 (Thorn EMI)

Derek Williams was the technical manager at Dragon Data from the early to final days.

In the beginning

“The original Dragon factory was in Mettoy’s Fforestfach premises. The person behind it was Tony Clarke (at that time Financial Director of Mettoy) who then hired me to help him get the Dragon computer from a prototype into a productionable form. The Dragon operation grew very quickly and Tony set up Dragon Data Ltd with Prutec as the main investor and it was then that production was moved to the Kenfig Hill site. At that time the Board was Tony Clarke (MD), Me [Derek Williams] (Technical Director), Richard Wadman (Sales & Marketing Director) and Maurice Wilde (Production Director), along with a Prutec Director.”

“The Dragon 32 came into being on the cusp of major change in the computing industry,

a time when power was shifting from hardware into software.

It was software that was starting to drive hardware sales with purchasers more interested in what the computer could do through applications,

rather than the box that delivered the application.

At that time there was also a big difference between a ‘Home’ computer and a ‘Business’ computer which Tony Clarke and I fully realised,

with one of the main driving factors being selling price.

Tony had modelled the Dragon computer on Radio Shack’s ‘Colour Computer’ because of the availability of software in the USA for this machine.

In the Autumn of 1982, Tony sent me to the US to visit various Colour Computer software producers to get European versions of their products.

I also attended Comdex in November 1982, the world’s largest computer expo. which was a sort of baptism of fire,

both to the USA (never visited the country previously) and also the emerging world market for computer hardware

& software. This trip and subsequent other US visits, including a meeting with Bill Gates in Q1 1983

when he showed me early renditions of what went on to be Windows products, changed the direction of my thinking.”

Big Disappointment

“The big disappointment with Dragon was the loss of Tony Clarke who went on holiday in August 1983 and never returned to the company. Tony was extremely entrepreneurial which is what was required for a company like Dragon that was very fast moving. Following Tony’s departure it was like the rudder had been shot off, the company totally lost direction, which is a great shame because it could have grown into a much larger organisation.”

Beyond the Dragon

“I originally came up with the Liberator idea whilst working at Dragon after seeing what was called “The Workslate” made by Convergent Technologies, Inc in San Jose, California. It was the worlds first production computer based on surface mounted components. When I got back from the US I had a letter on my desk at Dragon from Bernard Terry, Principle Consultant Central Computer & Telecoms Agency (CCTA) which was a UK Government Department. The letter had been sent to enquire if Dragon would be interested in developing a portable text processor for use by the Civil Service. I got together with Bernard and we jointly thrashed out an outline specification for the text processor. I then added the technical detail to the specification and put the project proposal to Dragon, but it was declined by the company’s Board. Just after Dragon was put into Liquidation by Prutec I got a call from a person in the Dept Trade & Industry who gave me a contact at Thorn EMI and suggested I talk to them to see if they would be interested in taking the text processor project on. I met with Colin Southgate, Group MD of Thorn EMI IT and he liked the project and asked me to put a development team together which I did from ex-Dragon staff, within 2-3 weeks we’d all been hired by Thorn EMI.”

Q & A

Dragon 32 :

Q : Moving from a prototype to a full production machine is a not an easy task, what were the challenges in making this happen (for the Dragon 32)?

A : “The big production bottleneck was testing. Whilst we were still in the Mettoy building I designed a test rig using a Dragon 32 to test production machines. The test software was written by Duncan Smeed and then modified by myself for the production version.

Before production of the Dragon

computer started at Mettoy there were various prototypes built. The first

few Dragon’s only had 16k of memory but Tony pushed to get the memory

upgraded to 32k and at that time, one memory maker had put together 2 x

32k wafers into one housing to make a 64k addressable memory chip, but

with many of these chips only one wafer worked. Instead of throwing the

whole failed 64k chip away, they cheaply sold the chips as 32k versions

and this was how the Dragon 32k came into being, using failed 64k chips.

Although he 32k chips worked very well, they consumed more power than the

original dragon power supply was designed to support so this had to be

quickly redesigned. Component cost was a big factor in the design of the

Dragon so all modifications were carefully thought through.”

Q : Why the 6809/6847 and the reference design for the Dragon 32, that was so very similar to the CoCo rather than other alternate options and was anything else explored?

A : “No other options explored, Tony’s idea was to leverage the software availability for the CoCo to give us a springboard into the market, it was what the computer could do (through software) that attracted buyers (who mainly wanted to play games).”

Q : What were the challenges with adding the extra memory to the 32 to create the 64?

A :

“The problem the Dragon 32 had was that it was stuck with the original Memory Map of the CoCo which placed the Basic Interpreter ROM at location 8000 – BFFF. With a small total memory architecture of 32k, this was not a problem, but moving up to a 64k machine the original memory map was highly inconvenient for application software. I worked out a scheme with Duncan Smeed (Software) to read the ROM into the upper part of the RAM and then switch out the ROMs so that the memory map was contiguous until the reserved upper section supporting the interpreter. ”

Q : In Nov/Dec 83 I found it very difficult to get a D64, having to phone the factory to see had taken delivery recently to get one. Why was there a shortage??

A : “If I remember correctly, it was down to a shortage of memory chips.”

Q : TANO (USA), any info on how this alliance came about?

A : “TANO had become aware of the Dragon 64 through complimentary comment in an article published in the US which talked about the innovative memory map solution we used for contiguous memory. The President and a couple of other execs from TANO visited Dragon earlier in 1983 and Tony and I returned the visit to their New Orleans offices later.”

Q :

Did Tano do all their own manufacturing? Boards, case etc. or buy in from DD?

A :

“I don’t remember any shipping arrangements for Dragon Boards going to the US so they must have made their own.”

Q : How bad were the Dragon 32 returns? Was it all centred around the SAM (MC6883/SN74LS783) chip or were there other issues?

A : “Yes, we did haver problems with the SAM chip, and it took around 2-3 months for Motorola to iron out the production issue and provide Dragon with replacement chips.

We had another problem that was getting reported by some customers of a power supply burn out, the major issue was repeating the problem in the workshop. Just like tracking down the source of a biological virus, we contacted all customers who had experienced the problem and cross referenced the operating scenario and realised that it was the cassette serial interface that was triggering the issue. In certain circumstances, the serial input voltage would go under zero and this triggered what’s called CMOS lockup (or latch-up) where an innocent looking input device suddenly becomes a power current sink. The solution being to simply add a diode to the input circuit to stop the input from going under zero volts. ”.

Q : Did the soak testing come about from the rate of returns? Did the soak test stay in place until the end as I understand it was quite an overhead on the production?

A : "The soak test was mainly there to iron out SAM chip problems."

Q : Who designed the Dragon 32 case?

A : “I don’t know who did the actual case design but the tooling would have been managed by Maurice Wilde (originally Mettoy and later Production Director of Dragon).”

Q : Who was the draftsman for the Dragon 32/64 schematics?

A : “The schematics were most probably produced by PA Technology”

Q : Do you have any info on the ‘Master’ test unit (looks like a modified

32 with a button panel), used on the production line (see attached

picture) to confirm correct operation of the ports, keyboard etc. We have

the source for the ‘slave’ test cart source (from Duncan) used for the

machine on test and I remember seeing comments with your name on them in

it?

A : “I designed the original Dragon test rig using a Dragon to test a Dragon. The software was a combination of Duncan and myself. ”

Q : In one of the Dragon 32 brochures there was the mention of 256K RAM upgrades and an additional 8bit microprocessor were these serious contenders for production?

A : “Lots of discussion but no, the idea did not move forward.”

Q : In some of the period news clips it looks like the Dragon 32 cases were being made in Swansea factory. Was this the case? And did the case moulding move to Kenfig? ?

A : “Dragon assembled and tested only with board and case manufacturing being outsourced”

Dragon General :

Q : What vision did you have for Dragon and beyond, and about the kind of team he was trying to build?

A : “The Dragon experience was unique because right from the word go in Mettoy’s Swansea factory things moved super fast. There were so many things to deal with on a constant basis that it was only Tony who was thinking about the future. My aim was to build a technically competent team who could take the initial Dragon design forward with new hardware and software support.”

Q : but one thing I've not been able to capture so far is the 'zeitgeist' at Dragon?

A : “In terms of the 'zeitgeist' at Dragon (as you call it),

this is an attitude that people have to have in a start up that is both

exciting and challenging which, coupled with a very fast moving

environment, this attitude generates a sort of a ‘can do’ approach to any

problem faced. Back in 1984, I remember reading an article about a book

called “The

Soul Of A New Machine” by Tracy Kidder.

This book captures the same feelings I experienced with the team that built the Thorn EMI Liberator.”

Q : We'd love to know more about the involvement of PA Consulting?

A : “PA, and in particular Ian Thompson Bell were only involved with Dragon at the very early stages whilst Dragon was still in Swansea.”

Q : Did working with PA halt with Tony leaving or for another reason?

A : “PA’s involvement had halted very early on and so nothing to do with Tony leaving.”

Q : We're the management team fervent users of the Dragon themselves? Perhaps with a full OS9 system? Also was the Dragon used internally for operational tasks? e.g. stock control??

A : “Yes, Tony, myself and Richard Wadman were active Dragon users, but for experience and development only. I’m not ware of anyone writing stock control software. ”

Q : What was Vivaways involvement in projects? As they can be seen as the authors of the ‘Extensions to OS-9 for the Dragon 128’ document by Paul Dyan.?

A : “Vivaway were involved through Ken Kaplan and Microware to port OS9 to the

Beta machine.”

Q : After the original Dragon 32 was completed, there was still involvement from PA and Vivaway, how come this wasn’t brought in house given there was good talent in Dragon’s technical team?

A : “There was no involvement of PA other than in the very early Mettoy days. Vivaway’s involvement came after Tony had left and following some issues with the Beta design team.”

Q : Do you recall any details of the relationship with Race Electronics who manufactured the main boards?

A : “The relationship with Race was very cordial, they were competent and had a good manufacturing facility in Llantrisant, South Wales.”

Q : How much work was done in house, burning EPROMs etc., rather than outsourced?

A : “The use of EPROMS would only have been for development and very early production. Only prototypes would have been built in house, all manufacturing was outsourced with Dragon’s facility being used for final assembly and testing.”

Q : Was Tony Clarke OK? Did he go do something else or was he maybe burnt out from the prior two years?

A : “Tony’s departure was quite a shock. None of the rest of the management team could understand why he left. Prutech tried to incentivise him back, but it was clear that he had made up his mind to leave.

Tony was very entrepreneurial and had the right mindset to run a very fast

moving company such as Dragon and had he stayed I think the Dragon outcome

would have been very different.”

Q : In

our intial contact you said that you saw the “The Workslate”, which sparked the Liberator idea. Did you see this in the USA on a Dragon Business trip? If so what did this trip involve?

A : “I was in San Diego visiting a Software supplier who furnished Dragon with a Disc Operating System (DOS) to support an external floppy drive for the Dragon 64 when I saw a picture of the Workslate on the cover of a Magazine. I was immediately taken with the size and capability of the Workslate and because it was a production item, my immediate thoughts were that Dragon could import the product to sell and support it in the UK & Europe. I called up Convergent Technology in San Jose (the manufacturers) and then flew up to meet with them to discuss the distribution idea. Initial discussions went well so I purchased a Workslate to show to the board of Dragon. When I returned from the US trip, on my desk was a letter from Bernard Terry of the Government Central Computer and Technology Agency who were looking for a UK company to make a portable text processor for use by the Civil Service. It seemed to me a fortuitous opportunity, so I called up Bernard and I took the Workslate to show him and discuss the fit with the CCTA requirement. Bernard listened intently to my Workslate pitch to fulfil their requirement, but the proceeded to explain why the workslate would not be suitable. Following this meeting, back at Dragon I put together a specification for the sort of product that would fit the CCTA requirement and this was later accepted by Bernard’s team. However, when I pitched the development idea to Dragon’s Board in May/June 1984, it was turned down because of the state of Dragon’s finances at that time. After I left Dragon in July 1984, I got a call at home from a person in the Dept Of Trade & Industry who suggested I contact Thorn EMI about the ‘Liberator’ project and he gave me a contact. Following a couple of quick initial meetings with Thorn I was introduced to Clin Southgate who was then Group MD of Thorn EMI IT Ltd who amazingly hired me on the spot and asked me to form a team to develop the Liberator project. I, John Peacock, Jan Wojna, Duncan Smeed & John Linney joined Thorn EMI one week later! (all being ex-employees of Dragon)”

Q : Were you involved with the Touchmaster tablet? Any more background on it? e.g. how it came into existence? How much DD design involvement?

A : “I had no involvement with Touchmaster”

Q : There are specific questions above the Beta etc. but was there an over arching new product strategy? I guess this changed overtime especially with the arrival of Brian Moore?

A : “To run a company such as Dragon which was very fast moving, you have to be very entrepreneurial and have market vision. Brian was a good manager but was totally unused to a company like Dragon which is not a criticism, but more like a square peg in a round hole.”

Q : I understand from Brian Moore that by the time he arrived Dragon was already in serious financial difficulty. What was your opinion on where it all went wrong? In hindsight, is there anything you’d have done differently?

A : “At the time that Tony left, it was true that Dragon had some problems brought about by production issues, but in my view, I think we could have weathered the storm. We needed to find new markets and products that had plenty of opportunity, had Tony been there I think we would have run with the Liberator project (the DTI gave a grant of £90,000 towards development) and could have sold a huge number into the Civil Service.”

Q : Do you know why the engineering were initially located in an

industrial unit the around the corner from the main building at Kenfig?

A : “When we moved to Kenfig, the target building was modified to include offices for admin and development”

Q : Do you know which building Dragon started in at Fforestfach site, as we haven’t been able to find it. Assuming it didn’t burn down and that's why we can't find it?

A : “The production started in the Mettoy factory in an area that Maurice Wilde had set aside and this was separated from the rest of Mettoy.”

Q :

There's a photo of the Liberator team at Thorn, with John Peacock in it,

was he also at Dragon?

A : “John Peacock

joined Dragon as Finance Manager just before the move from Mettoy to

Kenfig Hill. He reported to Tony Clarke.

I got to know John very well whilst at Dragon and realised he had many supplementary skills particularly in respect of working with suppliers. When Colin Southgate asked me to put the Liberator team together John was an obvious choice of Admin Manager because I knew that he would be a great asset to manage the project finance, providing monthly accounts to Thorn EMI IT and also assisting with many different suppliers.”

Q : What was your most memorable DD story/memory?

A : “There are many but I will never forget the doctrine of fire I got when, having never visited the USA before, in late 1982 Tony sent me to Comdex in Las Vegas on my own to meet with CoCo software developers. Las Vegas being a rather incredible introduction to the US!”

Prototypes (Beta) :

Q : The “Dragon Business Machine” was said to have being developed by PA, how much development did they do on the project? (WDA Memorandum, P6 J/iv)?

A : “If you are asking about the planned Dragon Business Machine to enter the business market, PA were not involved at all. I was very aware of what was happening in the US market and realised that the key to any business PC was software. Porting software to a PC with custom architecture was a significant task but until the IBM PC set the world standard with PC DOS (MS DOS) which defined an API (Application Program Interface), there was little alternative. The API allowed software developers to write software which was mostly independent of the PC hardware”

Q : How close to being finished was the Beta when DD folded? Can you remember if there were many changes still

"pending" in terms of hardware and software revisions?

A : “The truth is that changes were ongoing due to a number of influences. I don’t remember the circumstances, but I met with Ken Kaplan of Microware, the originator of the OS9 operating system software and he was urging us to use OS9 on the Dragon Beta PC. Following Tony’s departure from Dragon in the summer of 1983, both myself and Richard Wadman (Sales & Marketing) at Dragon were becoming nervous of the changing nature of the business computing market during the autumn of 1983 and early 1984. Tony was without doubt, the visionary leader that drove Dragon’s direction, so his loss was major. Dragon had always used Motorola chips but the IBM PC used Intel chips (8086 family) with PC DOS support, OS9 was written for the Motorola 6809 and 68000 processors so was a natural partner for Dragon. ”

Q : The text modes look like they were designed to be Teletext-like, presumably this was for compatibility with Prestel?

A : “Back in the 80’s computers used a Command Line Interface (text input) from a keyboard, and it was pretty obscure. It was only when new graphics chips came out coupled with larger memory chips that Windows appeared in the form of Windows 3 in the summer of 1990. Bill Gates had originally shown me a very noddy version of the sort of GUI (Graphical User Interface) that migrated to Win 3 back in late 1983, but at that time there was no chip availability to support a GUI.”

Q : Did hardware design (for the Alpha/Beta) move in house after Tony or

was that already in motion?

A : “The development of the Alpha/Beta was always in house from the very start.”

Q : What was the original concept/market position for the Beta, in comparison to how it ended up?

A : “As I have explained above, the timing of the Beta was unfortunate due to the turbulent period the market for business computing was going through. Also without Tony, the beta development was more of a case of ‘we’ve started, so lets finish’. ”

Prototypes (Other) :

Q : In an interview with Tony Clarke in July 83 Dragon User, he talks about a "£400 machine to follow the Dragon 64", possibly using the NEC u7220 graphics chip and twin 6809s - any idea what happened to this plan? And there's talk of a "68000-based and 8086 based machine" costing £2,000. Neither of these projects sound like the Alpha or the Beta. How far did these ideas progress and did you see it?

A : “We definitely were thinking of a 68000 based machine, but at the time the chips were too expensive for the sort of price point we wanted to hit. Thinking was very much along the lines of a 6809 machine running OS9.”

Q : Another prototype rumour included a school machine (Educational Unit) with a built in monitor - again, any memories of this? (WDA Memorandum, P6 J/iii)

A : “We did talk about a Dragon version to rival the BBC computer, but nothing was progressed.”

Q : Dragon "Future Home Unit" with voice and Prestel - again, any memories of this? (WDA Memorandum, P6 J/v)

A : “I did experiment with a dial up Prestel card but again, it did not get very far.”

Q : Also, any memories of the MSX? The prototype we've seen was made by Radofin in the Eurohard era, but there was talk of a Dragon MSX before that, in the GEC era, and talk of it being a more upmarket machine with a built in floppy. How far did this plan get?

A : “Again the MSX was a concept but no reality.”

Post Dragon :

Q : Did you have any more involvement with Dragon after leaving?

A : “None.”

Q : What did you do after the Liberator project?

A : “A couple of other amazing projects which are stories in their own right, but won’t go into that now.”

Q : Z80 Vs hd6309? What swung the decision away from a CMOS 6809 part (for the Liberator)??

A : “The Liberator was not a piece of technology looking for a market but more of what technology is required to fulfil an application brief. The focus was on low power consumption and what architecture could best support the CCTA requirements.”

Q : A load of Liberator cartridges came on eBay recently. Can you tell us anything about what they offered? ?

A : “The Liberator achieved many amazing objectives. Think of how you develop a small A4 sized laptop computer when you have no screen, no hardware, no case design, no keyboard and there are no other examples of such a device out there (other than the Workslate which was built after multi-millions of investment and a purpose built factory to assemble surface mount technology). Oh, and you have to do it in 6 months from start to finish and deliver the first 40 units to the CCTA. Oh so you also have to develop a custom gate array in Silicon Valley to drive the largest LCD screen available from a Toshiba lab in Japan. Oh, you also have to cope with the fact that the outfit that was selected by Thorn to assemble the first 40 units went on strike a month before the delivery date. Oh, you also have to cope with the fact that it can take 3 months to cut injection mould tooling for a case structure that kept moving. I think the team did rather well delivering the first 40 units exactly as contracted with the CCTA.

Colin Southgate who, shortly after hiring me and the team that build the Liberator went on to become Chief Exec of the Thorn EMI global empire and so lost his focus on our group. The new head of Thorn EMI IT was shocked to discover the Liberator team and had no idea how to handle us. I was told that marketing and manufacturing involvement with the Liberator was not of my concern despite being the main person behind the development and customer contact (the CCTA). Needless to say, Thorn EMI IT lost a rather easy mega market and a huge business opportinity, quite unbelievable!”

"Derek was a great salesman and always had his sleeves rolled up"

-

John Linney